How To Remove Stuck Spark Plug From Aluminum Head?

Looking for a step-by-step guide to safely remove a stuck spark plug from an aluminum head? You’ve come to the right place then.

A stuck spark plug in an aluminum head can send shivers down any car owner or mechanic’s spine.

The fear of damaging the softer aluminum, leading to a hefty repair bill, is real. But fret not! This guide is your personal toolbox of tricks, helping you navigate this situation with precision and care

We’ll show you how to remove the spark plug safely, ensuring your aluminum head stays pristine!

Removing a Stuck Spark Plug from an Aluminum Head (8 Steps)

1. Allow the Engine to Cool

- Preparation: Ensure the engine is completely cool before attempting to remove the spark plug. Working on a hot engine increases the risk of head damage and personal injury.

2. Clean Around the Spark Plug

- Removing Debris: Use compressed air or a soft brush to clean around the spark plug area. This prevents any debris from entering the combustion chamber during removal.

3. Apply Penetrating Oil

- Lubrication for Easing Removal: Liberally apply a quality penetrating oil around the spark plug base. Allow it to soak for at least a few hours, or overnight if possible, to help loosen the plug.

4. Use the Correct Tools

- Tool Selection: Select a spark plug socket that fits the plug exactly, along with a ratchet or T-handle designed for spark plug removal. A properly fitting tool is crucial to prevent slipping and rounding off the plug.

5. Apply Gentle Pressure

- Technique: Attach the spark plug socket and ratchet. Apply slow and steady pressure in the counterclockwise direction. Avoid using excessive force; if the plug does not begin to loosen, apply more penetrating oil and wait longer.

6. Increase Leverage Carefully (If Necessary)

- Advanced Technique: If the spark plug remains stuck, carefully use a breaker bar to increase leverage. Keep the tool as straight as possible to avoid putting uneven forces on the plug.

7. Heat Application (Last Resort)

- Careful Heating: As a last resort, applying gentle heat around the spark plug well (not directly on the plug) with a heat gun can expand the aluminum slightly, potentially easing removal. Proceed with caution to avoid overheating any area.

8. Inspect and Prepare for Replacement

- Post-Removal: Once removed, inspect the spark plug thread and head for any signs of damage. Use a thread chaser to clean and repair the threads if necessary before installing a new spark plug.

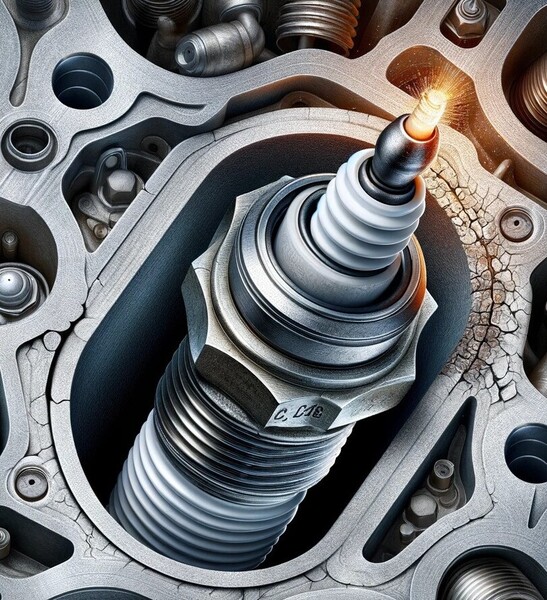

What Causes a Spark Plug to Get Stuck?

Several factors can contribute to a spark plug becoming stuck in an aluminum head, including:

- Corrosion and Rust: Over time, moisture and environmental factors can lead to corrosion around the spark plug threads, effectively bonding the plug to the head.

- Over-Tightening: Excessive force when installing the spark plug can cause thread distortion and make removal difficult.

- Heat Cycling: The engine’s heat cycling can cause the aluminum head to expand and contract around the steel spark plug, leading to a tighter fit.

- Carbon Build-Up: Combustion residues can accumulate around the spark plug, acting as an adhesive that makes removal challenging.

Can I Use WD-40 to Remove a Stuck Spark Plug?

While WD-40 is a versatile lubricant, it’s not the most effective choice for loosening a stuck spark plug.

Its primary use is for water displacement and general lubrication, but it does not have the penetrating power required to free up corrosion and rust effectively.

For spark plug removal, a dedicated penetrating oil is recommended.

What is the Best Penetrating Oil for Stuck Spark Plugs?

The best penetrating oils for stuck spark plugs have high solvency and low viscosity, allowing them to penetrate tight spaces and break down rust and corrosion.

Products such as PB Blaster, Liquid Wrench, or Kano Kroil are highly regarded for their effectiveness in loosening stuck metal components, including spark plugs.

These oils are specifically designed to penetrate and lubricate under extreme conditions.

How Tight Should Spark Plugs Be in Aluminum Heads?

Spark plugs should be tightened to the manufacturer’s recommended torque specifications, especially in aluminum heads which are more prone to stripping than iron heads.

Generally, the torque setting for spark plugs in aluminum heads ranges from 10 to 20 foot-pounds (13.6 to 27.1 Newton-meters), but always refer to the engine or spark plug manufacturer’s specifications.

A torque wrench should be used to ensure accurate and consistent tightening.

What Happens If You Don’t Torque Spark Plugs?

Failing to torque spark plugs to the correct specification can lead to several engine problems:

- Under-Torquing: Can cause the spark plug to loosen over time, potentially leading to combustion gases escaping, reduced engine performance, and even engine damage.

- Over-Torquing: Risks damaging the spark plug or stripping the threads in the aluminum head, which can be costly to repair. Over-tightening can also distort the spark plug’s metal shell, affecting heat dissipation and leading to overheating.

Final Thoughts

Understanding the causes of stuck spark plugs and how to address them with the right tools and products is essential for maintaining your vehicle’s engine health, especially when dealing with aluminum heads.

Always consult your vehicle’s service manual for specific recommendations and torque specifications to prevent issues related to spark plug installation and removal.

We hope that our guide on how to remove a stuck spark plug from aluminum head was helpful to you, please bookmark it for future reference if you need to 🙂

Related articles:

- Why Is My Steering Wheel Making Noise?

- How To Check Car Battery Health Without Multimeter

- How Far Can You Drive With A Blown Out Spark Plug?